SPTC Brief: Increasing Service Life of Concrete Structures Through Mitigation of ASR

January Edition

OVERVIEW: Alkali-silica reaction (ASR) is an expansive reaction between the alkalis in the cement and reactive silica in the aggregate particles. Arkansas is currently witnessing the detrimental effects of ASR at various locations within the state. These locations include many miles of interstate pavements and interstate barrier walls (locations in both Central and Northwest Arkansas). A petrographic analysis of samples from select locations has confirmed that ASR is present. Current research at the University of Arkansas has shown that concrete expansion due to ASR may have been exacerbated by the extreme weather changes that Arkansas has experienced during recent winters. This weather change has resulted in freezing and thawing cycles in both the pavement and barrier wall and has caused further deterioration. Therefore, prevention and mitigation measures must be developed. This project examines the effectiveness of silane and other potential sealers in stopping ASR in concrete structures.

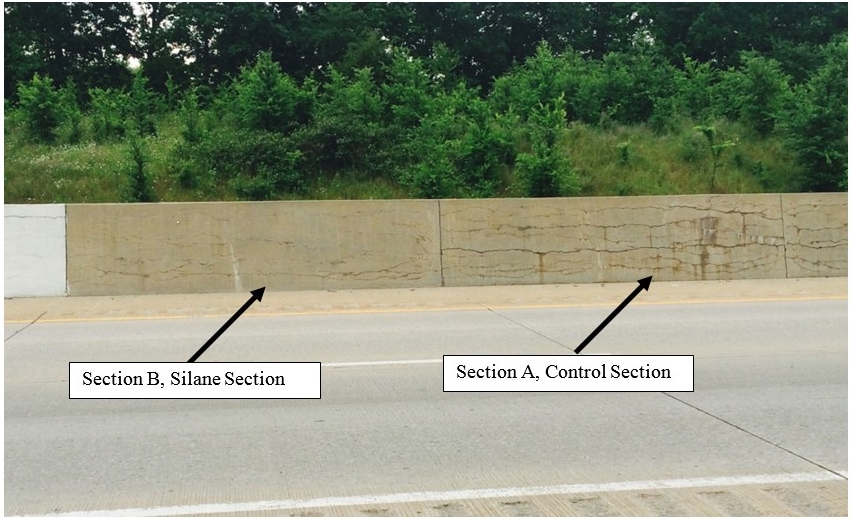

Figure 1: Moderately Damaged Section of the Barrier Wall Treated with Silane

The reaction between the cement and aggregates takes place when the highly alkaline pore solution corrodes and dissolves reactive siliceous minerals within the aggregate particles. The reaction between cement and aggregate is controlled by two factors. First, the cement alkali levels, which are reported as total alkali equivalents, control the alkalinity of the cement pore solution. Second, the presence and composition of reactive siliceous minerals within the aggregate particles determines the rate of reaction. An additional factor, which influences the development of alkali-silica gel, is the presence of calcium within the pore solution. For expansion to occur within the alkali-silica gel, a sufficient source of moisture must also be available. One of the major objectives of this project is to reduce the internal relative humidity by applying silane to the ASR infected concrete.

Silane is a penetrant that bonds to the surface of the concrete and forms a hydrophobic layer, which blocks liquid water from entering the concrete while allowing water vapor to escape. Over time, the silane treatment dries the concrete towards equilibrium with the surrounding air. If the internal relative humidity of the concrete drops below 80 percent, expansion will slow or cease. The research program is using silane and other topical applications to reduce the internal relative humidity of concrete structures infected with ASR.

Figure 2: Expansion of the Moderately Damaged Section of the Barrier Wall

The project is divided into two phases. In the first phase, expansion in the barrier wall and pavement is being monitored. Silane and other topical treatments have been applied to the barrier wall (Figure 1) and pavement.

The barrier wall is instrumented so that expansion and relative humidity can be monitored. Expansion data (shown in Figure 2) of the moderately damaged section of the barrier wall show the effectiveness of the silane. The sections treated with two applications of silane (labeled S2-2 in Figure 2) experienced approximately 50 percent less expansion than the control section. In the laboratory phase (second phase of the project), field exposure blocks containing reactive silica were cast (Figure 3).

Figure 3: Outdoor Exposure Blocks

Each block was instrumented so that expansion and relative humidity could be monitored. These blocks were treated with silane and other sealers to determine the most effective treatment that can mitigate ASR expansion by reducing internal relative humidity.

APPLICATIONS/IMPACT: The application of the results will improve the understanding of the effects of silane and other potential surface treatments on ASR infected concrete that are also subjected to extreme weather events. The research will also help determine the dosage rates and application frequency for silane and other potential surface treatments. The impact of the research is visible on the barrier wall. As shown in Figure 4, the control section, Section A, of the barrier wall exhibits more distress than the section treated with silane, Section B.

Figure 4: Barrier Wall Sections

Section A was left untreated, and two applications of silane was applied to Section B approximately three years ago. If left untreated, Section B would now resemble Section A.

BENEFITS: Applications of the findings are expected to increase the service life of concrete structures that exhibit distress caused by ASR and freezing and thawing.

About the Researchers

Micah Hale, Ph.D. P.E. is the Principal Investigator on this project. He is a Professor of Civil Engineering at the University of Arkansas. Richard Deschenes, Jr. is the graduate research assistant (University of Arkansas). Richard is a recipient of the Eisenhower Fellowship and the ACI BASF Construction Chemicals Student Fellowship.

The Southern Plains Transportation Center is a consortium of eight universities in U.S. Department of Transportation Region VI: the University of Oklahoma, Oklahoma State University, Langston University, University of Arkansas, University of New Mexico, Louisiana Tech University, University of Texas at El Paso and Texas Tech University.

The SPTC provides a unique opportunity through multi-institutional initiatives to develop comprehensive, cost-effective, and implementable solutions to critical infrastructure issues facing the transportation systems of the region and the nation, and to prepare transportation professionals for leadership roles through Research, Leadership, Collaboration, Education, Outreach, Tech Transfer and Workforce Development activities.