SPTC BRief: Evaluation and Repair of Existing Bridges in Extreme Environments

November Edition

OVERVIEW: Aging or deterioration of the nation’s bridge infrastructure is a significant issue that requires attention, especially for bridges subject to extreme environments and a changing climate. Causes for much of this deterioration are attributed to corrosion and metallic fatigue, both of which work together to reduce the strength and service-ability of bridge components over time. In many cases, strengthening of the locally affected bridge components using localized retrofits is an economical and fast alternative to complete bridge replacement. The objective of this research was to increase the understanding of corrosion effects in prestressed concrete bridges and longevity of existing steel bridges subjected to corrosion induced deterioration and metallic fatigue.

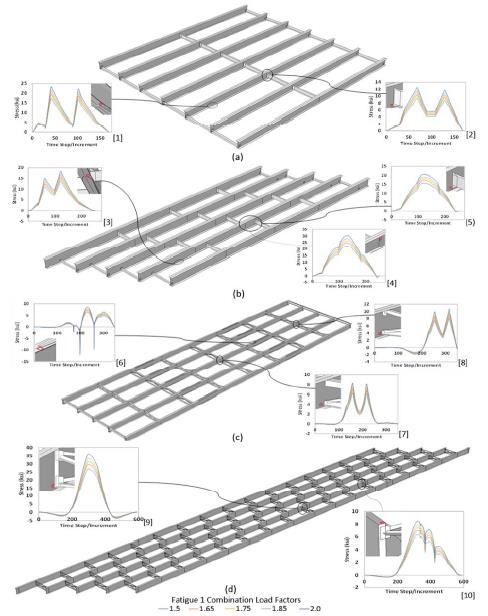

Figure 1 Stress History of Structural Steel Details

RESEARCH SUMMARY: This project consisted of analysis and experimental testing of steel bridge details susceptible to fatigue and end regions of precast prestressed concrete girder ends subjected to reinforcement corrosion. Locations most affected by fatigue were identified and detailed analyses were conducted for four bridges (Figure 1).

The steel bridges portion of the research was conducted in two parts. Part 1 began with an investigation of common bridge types within Region 6 and a selection of four distinct bridges for analysis. Next, detailed finite element models simulating all bridge connection geometries were analyzed, considering the American Association of State Highway and Transportation Officials (AASHTO) Fatigue I Load Model. Finally, stress analyses were conducted and local stress ranges were characterized to determine the location of fatigue-critical connection details within each bridge. In Part 2, localized fatigue retrofits capable of extending the steel component fatigue life were developed using prestressed carbon fiber reinforced polymer (CFRP) materials. Part 2 began with the development of the retrofit configuration, then a fatigue evaluation was conducted on the critical fatigue detail in each bridge based on the Goodman fatigue criterion and the retrofit configuration. Finally, the retrofit was tested on a welded diaphragm to girder connection detail in the laboratory.

The Goodman fatigue evaluation showed that skewed bridge construction is more damaging to the steel cross-frame-to-girder component fatigue life than non-skewed construction. Using the Goodman criterion, the prestress force required to shift a structural detail from a state of finite fatigue life to infinite fatigue life increases linearly with the applied stress range; however, the magnitude of the prestressing force is dependent on the size of the steel member cross-section. Laboratory tests were successful in shifting the mean stress in an instrumented steel beam using the localized prestressed CFRP retrofit. Although this experiment only provides a preliminary evaluation of the retrofit performance, the results indicate that the retrofit is capable of reducing the mean stress of structural details therein improving fatigue performance.

The concrete portion of this research project was divided into two sections: lab experiments and field inspections. Lab experiments to accelerate corrosion in end regions of half-scale AASHTO Type II girders that replicate girders from a bridge taken out of service in 2013 (I-244 bridge over the Arkansas River in Tulsa County) were conducted. Nine girders were constructed with an emphasis on consistency with the original design and engineering properties. One end region of each girder was exposed to an accelerated corrosion process. Three different levels of corrosion exposure were applied to the nine girders to illustrate varying environmental conditions. Six of the girders were shear tested with end zone deterioration. Shear tests resulted in measured shear values less than the design shear capacity for each girder (Figure 2). The corroded ends of the members exhibited larger measured shear strengths, and exhibited earlier bond loss than the control ends. The exact significance of these results is unclear, but the results indicate an effect of strand corrosion on the failure mechanism. Further research including additional deterioration levels is necessary to clarify the results.

Figure 2 Experimental Shear Capacity Comparison

Concurrently with the lab experiments, efforts were placed on inspecting similar bridges to those used in the research project (bridges with AASHTO Type II prestressed girders constructed in the 1960s and 1970s) to identify varying levels of visible corrosion deterioration. During the inspections, various deterioration characteristics were found at multiple sites.

Those deterioration characteristics included: corroded bearing plates; corroded anchor bolts and nuts; spalling above the support; exposed rebar and prestressing strands; diagonal cracking of the back corner of the girder; vertical cracking along the girder and diaphragm interface; diagonal cracking from the top flange and web interface; and diaphragm deterioration. These common deterioration characteristics did not appear to correlate directly with the superstructure ratings.

IMPACT: The research addressed problem areas for corrosion and fatigue in the two most common type of bridge structure in Region 6. The localized retrofits have the potential to extend the life of in-service steel bridges subject to damage from fatigue at cross-frame details and are almost instantly implementable. However, additional research is warranted to identify methods for reducing prestress losses in the retrofit and in surface preparation for mounting. A number of common deterioration characteristics were noted for prestressed concrete girder ends for in-service bridges in Oklahoma. Several potential steps could be implemented to reduce the impacts of this deterioration. These include ensuring proper functioning of expansion joints to prevent exposure of the girder ends to deleterious materials and coating bearing plates, anchor bolts, and nuts.

About the Researchers: Dr. Royce Floyd from the School of Civil and Environmental Engineering at The University of Oklahoma (OU) was the Principal Investigator, and Dr. Gary S. Prinz from the University of Arkansas (UArk) – Department of Civil Engineering served as Co-Principal Investigator. Masters students in the School of Civil and Environmental Engineering at OU, Korey Pough and Darion Mayhorn, also contributed to the project.

The Southern Plains Transportation Center is a consortium of eight universities in U.S. Department of Transportation Region VI: the University of Oklahoma, Oklahoma State University, Langston University, University of Arkansas, University of New Mexico, Louisiana Tech University, University of Texas at El Paso and Texas Tech University.

The SPTC provides a unique opportunity through multi-institutional initiatives to develop comprehensive, cost-effective, and implementable solutions to critical infrastructure issues facing the transportation systems of the region and the nation, and to prepare transportation professionals for leadership roles through Research, Leadership, Collaboration, Education, Outreach, Tech Transfer and Workforce Development activities.